Nov 13, 2020

Marine Application Testing on PRE Labs Carrier Systems

When testing the impact of marine applications on body armour, there are four main components to consider when exposing the carrier to moisture and salt-water conditions; discoloration or bleaching of fabrics, hook and loop adhesion, metal component finishes, and the integrity of the soft armour panels.

Discoloration of Fabrics

PRE Labs uses Cordura® nylon fabrics in the construction of its carrier systems. This material is highly durable and resistant to wear.

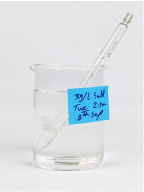

Nylon fabric samples were submerged in water containing sea salt with a concentration of 30 g/L - similar to the characteristics of sea salt - for one week at room temperature. There was no colour bleeding or bleaching detected after this exposure. Additionally, there appeared to be no changes to the durability or flexibility of the tested materials.

30g/L salt water solution with observed zero colour transformation.

30g/L salt water solution with observed zero colour transformation.

VELCRO® adhesion to nylon fabrics test under marine conditions.

VELCRO® adhesion to nylon fabrics test under marine conditions.

Velcro® Bond To Fabrics

Industrial strength Velcro® hook and loop fasteners are used throughout PRE Labs carrier systems. Samples were attached to the nylon fabric and exposed to a 30g/L salt water solution. They monitored for one week to see if there was any changes in bond to the fabric. There was no change observed in the time period and the Velcro® maintained an excellent adhesion property. Salt crystallization did occur and can be washed out during proper care and maintenance of the carrier.

Metal Component Testing

PRE Labs uses Fidlock® buckles in many of its tactical armour systems and armour components. They are self-aligning, ultra-strong, and field replaceable.

In an internal test, the metal components were exposed to a continuous salt spray for 48 hours to monitor any changes. Of the 13 components tested, only three parts produced small amounts of surface rust that did not appear to affect the integrity or functionality of the components.

PRE Labs uses high-performance, field replaceable components.

PRE Labs uses high-performance, field replaceable components.

PRE Labs Ballistic Panels

PRE Labs' Level II and IIIA NIJ 0101.06 Certified ballistic panels are ultrasonically sealed in waterproof pouches to protect against exposure to moisture, ultraviolet radiation, and damaging chemicals. This offers the wearer the utmost in protection and performance from their body armour.

PRE Labs In-House Testing Capabilities

Our team is driven by decades of field experience and the science of survival. PRE Labs’ in-house scientists and engineers explore how the materials we use are impacted by various environmental conditions, and how we can design body armour to better protect against ballistic impacts.

Get Updates From The Lab

Sign up and be the first to hear about new products and innovations from PRE Labs.